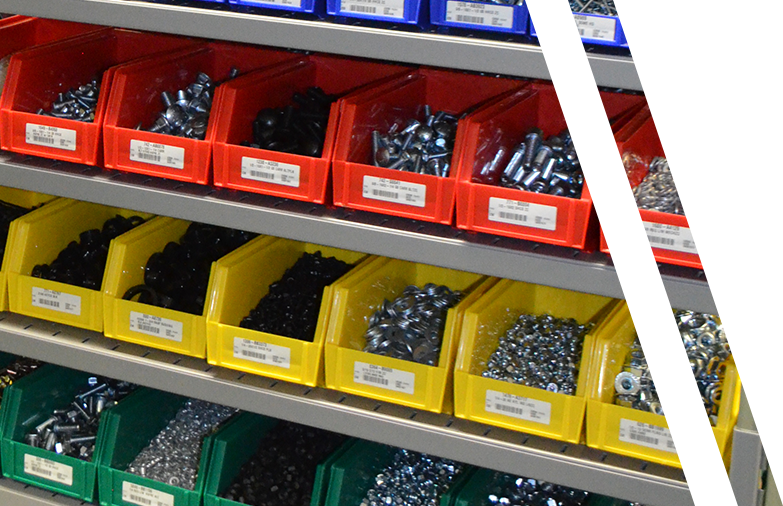

Single-bin System

Excess inventory can sometimes be a pain and take up valuable space. Conversely, too little inventory can also be a costly situation and take up valuable time. With our single-bin system, those are a thing of the past. With our products being stored and managed in a single, volumetrically sized bin per SKU, your inventory levels will stay where you need them to support current production levels. Endries dedicated account manager will review each product to ensure every part is reordered as needed.